3 viable OPTIONS for Compressed Air Pipe

Aluminum Pipe

Our Choice at A10 Compressed air services is an aluminum pipe. Aluminum pipe is lightweight, fast to install, has many fittings that make installation quick, doesn’t require an open flame or sparks when installing, and looks excellent with its blue color denoting “air” throughout your operation. Aluminum pipe systems can help meet the requirements of ISO 8573-1: 2010 air quality standards, should the application require it. Cleaner air also means lower maintenance costs.

Copper Pipe

It has been proven that copper pipes are a good solution for compressed air piping. It will not rust and, with proper soldering, won’t leak. However, copper pipe is quite expensive and requires a professional instillation . In our experience, it also takes longer to install and is more challenging to add lines to your system when you need to upgrade. Another downside is the open flame required to solder copper pipe which can be prohibited in many industrial facilities due to the risk of explosion.

Stainless Steel Pipe

Stainless Steel pipe is an option for compressed air and has often been used in many piping air facilities. In our experience, using this option is very labor-intensive due to the amount of effort required to seal it from leaks properly. The compressed air provided by this system built with steel piping has a higher level of contaminants than the exact same system would have if aluminum piping was used instead.

4 BENEFITS of Aluminum Pipe

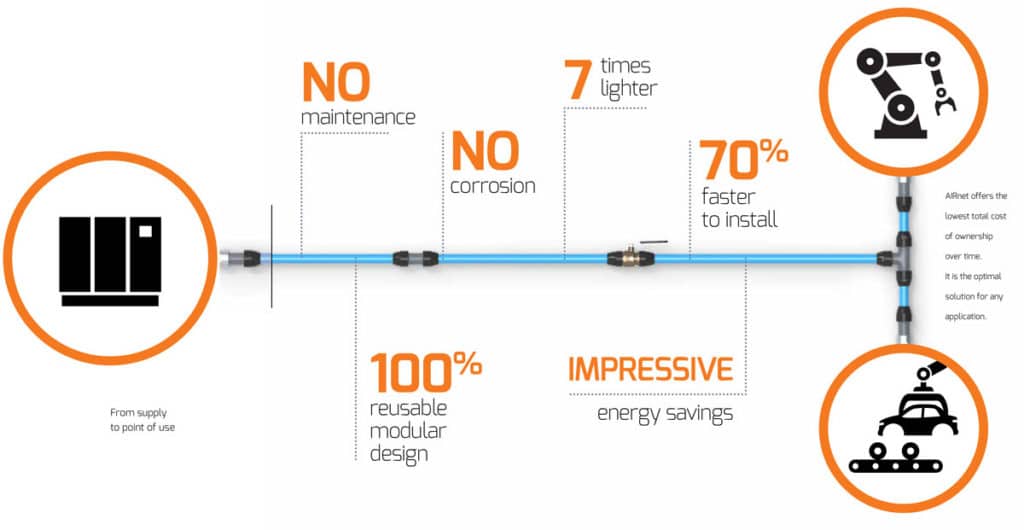

1. Lightweight

Steel has a strength-to-weight ratio that’s about five times greater than aluminum. However, stainless steel is hefty due to its density, making it harder to transport while using less material in production compared with aluminum. An aluminum air pipe is about one-third the weight of a stainless steel air pipe.

2. Fast Installation and easily modifiable.

- No heavy tooling or machinery required

- Quick connections with no need to crimp, thread, solder, or glue the pipe

- Pipe fittings can be assembled by hand due to the wide availability of quick-connect fittings, a push of the pipe into the fitting is all it takes

- Modular design supports extensions and modifications to meet new demands

- Components are interchangeable and reusable after disassembly

- Quickdrops are easily mounted, both horizontally and vertically

3. Many fitting options

Traditional fittings require you to cut pipes every time a new drop needs to be added. Quick drop fittings also allow easy installation after your compressed air system is already in place. Quickly attach the quick drop to any portion of your header pipe and begin drilling your connection. With many push-in fittings, from elbows to couplings, etc. all designed for fast installation it is the perfect choice for your next project.

Time is money, that much is true for every business especially when every person installing pipe in your system receives a check. While the initial cost of quick drop fittings does trend on the higher side than the cost of traditional connectors, this cost is saved during installation with the time and expenses paid.

4. Local Installers can get you up and running quickly

Local Air Compressor distributors have teams experienced in getting you up and running quickly with aluminum pipe.

With many years of experience, A10 can build a strategic plan that will be cost-effective and time-efficient to quickly build and install your aluminum compressed air system in your facility. We understand the complexity of installing aluminum air pipes in your facility.